News

Amid the wave of new energy vehicles, CNC mold customization is experiencing explosive growth.

date:2025-06-12

date:2025-06-12 click:

click:

"New Energy Vehicle Industry Drives Thriving Growth in CNC Mold Processing and Customization"

With the rapid global development of the new energy vehicle (NEV) industry, the CNC mold processing and customization sector has ushered in new growth opportunities. Industry data shows that in recent years, China’s NEV mold market size has reached 20 billion RMB, with a year-on-year growth of 35%. Among this, CNC customized molds account for over 60% of the market share.

"High-Speed Milling and EDM Boost NEV Mold Manufacturing into a High-Precision Era"

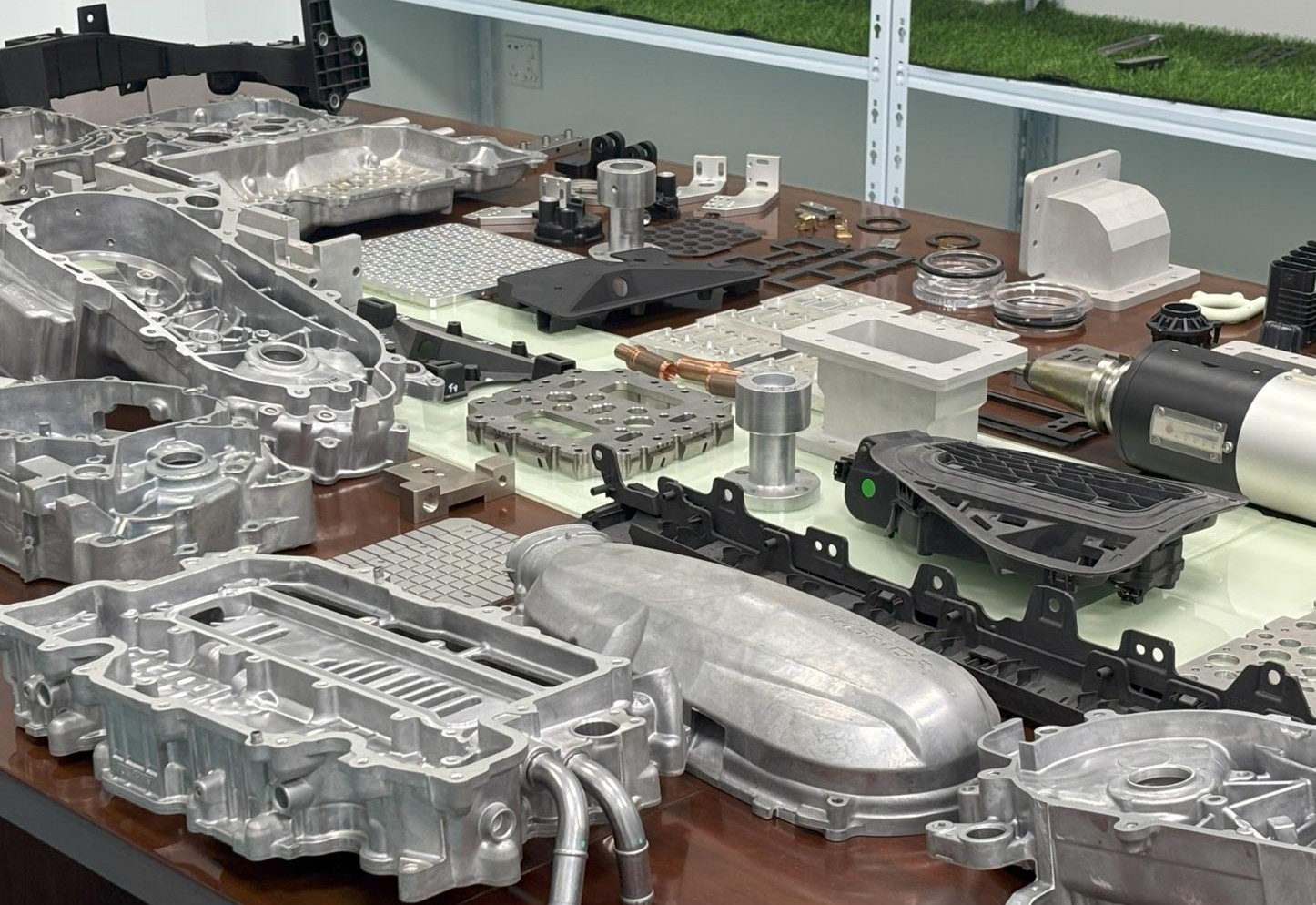

The structural differences between NEVs and traditional internal combustion vehicles impose higher demands on mold precision, performance, and production efficiency. To meet market needs, mold manufacturers have increased R&D investment and improved CNC processing capabilities. For example, Blue Ocean Molds has developed a series of specialized molds targeting key NEV components such as battery boxes and motor housings. By employing advanced CNC technologies like high-speed milling and electrical discharge machining (EDM), they have increased mold forming precision by 20% and reduced production cycles by 25%.

"NEV Precision Manufacturing Creates a New Blue Ocean for CNC Molds"

Industry experts analyze that the rising demand for lightweight, integrated, and precision components in NEVs is driving widespread application of CNC (Computer Numerical Control) technology in mold manufacturing. Compared to traditional molds, CNC customized molds offer superior precision, efficiency, and consistency, meeting the stringent technical requirements for core NEV parts such as batteries, motors, and vehicle body structures. Market forecasts indicate that as NEV penetration deepens and domestic mold manufacturing technology advances, the CNC customized mold market is expected to maintain rapid growth, potentially surpassing 30 billion RMB within the next three years. Meanwhile, industry competition will intensify, with enterprises possessing core technologies and automated production capabilities gaining larger market shares.

“Customization + Intelligentization Dual-Drive: CNC Mold Industry Embraces the New Energy Vehicle Dividend Period”

At the same time, new energy vehicle (NEV) companies are demanding increasingly higher levels of mold customization. To quickly respond to customer needs, mold manufacturers widely adopt digital design and manufacturing technologies, achieving intelligent management throughout the entire process from design to production. Cooperation between NEV manufacturers and mold suppliers has significantly accelerated the time-to-market for new products. Industry experts state that with the continued expansion of the NEV market, the CNC mold customization sector is set to enter a prolonged period of rapid growth, with the market size expected to maintain an annual growth rate exceeding 25% over the coming years.

Previous:

Previous: Back

Back