News

A New Path to Green Sustainability: CNC Mold Processing and Customization Empowering Industry Development

date:2025-06-12

date:2025-06-12 click:

click:

"Green Manufacturing Leading the Future: The CNC Mold Processing and Customization Industry"

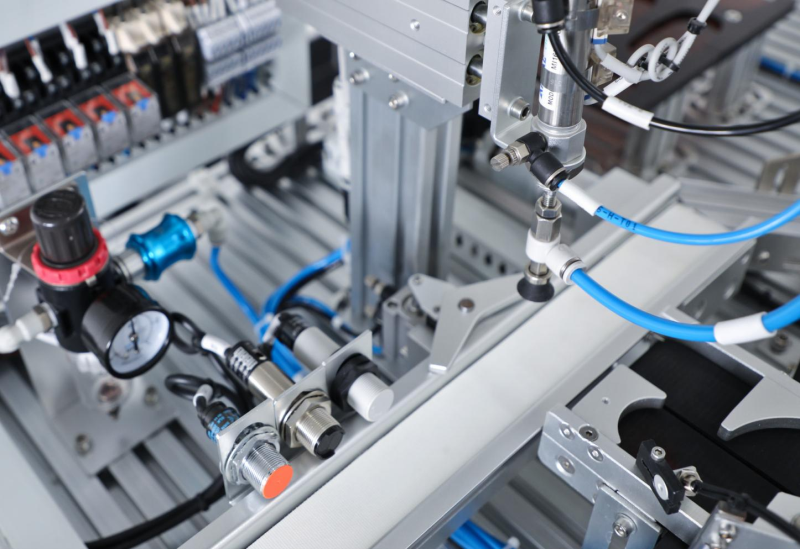

Against the global backdrop of advocating green development, the CNC mold processing and customization industry is actively exploring new paths for environmental sustainability, contributing significantly to sustainable development. With its high precision and low material loss, CNC technology has become a critical tool for implementing green practices in mold manufacturing.

"Green Manufacturing Practices in Mold Enterprises: Lightweight Design and Dry Cutting Technologies Driving Energy Savings and Emissions Reduction"

1. Industry Drivers for Green Manufacturing

As environmental regulations tighten globally (e.g., the EU’s “Green Deal” and China’s “Dual Carbon” goals), traditional energy-intensive and polluting mold production methods face increasing pressure for transformation. Meanwhile, growing demand for lightweight and recyclable molds from downstream industries is pushing companies to adopt green technologies such as CNC processing. Utilizing digital programming and automated control, CNC technology can reduce material waste by over 30% and significantly lower carbon emissions.

2. Eco-Friendly Practices in CNC Technology

Lightweight Design: Through topology optimization and simulation analysis, CNC machining enables precise weight reduction in mold structures, minimizing raw material consumption. For example, one company replaced traditional steel with aluminum-magnesium alloys, reducing mold weight by 20% while extending its lifespan.

Green Processes: Techniques like dry cutting and Minimum Quantity Lubrication (MQL) eliminate cutting fluid pollution and reduce energy consumption by 15%-30% [Note: Data source needed].

Circular Economy: The precision of CNC machining supports mold repair and remanufacturing, minimizing resource waste.

3. Market Competitiveness and Future Outlook

Green manufacturing is not only a compliance necessity but also a core differentiator for businesses. Research indicates that 80% of buyers prefer mold suppliers with environmental certifications. In the future, with the integration of artificial intelligence and IoT technologies, CNC machining will further enable intelligent, energy-efficient production, driving the industry toward the goal of "zero-waste factories."

"Green Manufacturing Empowering the Mold Industry: New Opportunities Driven by Environmental Policies and Market Demand"

The promotion of green manufacturing concepts not only aligns with national environmental policy requirements but also brings new development opportunities for mold enterprises. As consumer demand for green products rises, mold companies adopting green manufacturing technologies will gain a stronger competitive advantage in the market.

Through technological innovation, CNC mold processing and customization is reshaping the manufacturing ecosystem—from “high energy consumption” to “precision intelligent manufacturing.” This approach not only responds to global sustainability initiatives but also opens new growth avenues for businesses.

Previous:Global Precision Customer Acqu

Previous:Global Precision Customer Acqu Back

Back