News

The Rise of Domestic CNC Systems: Breaking the Import Monopoly in Mold Processing and Customization

date:2025-06-12

date:2025-06-12 click:

click: "Core Technologies Under Control! Domestic CNC Systems Usher in a New Era for Mold Processing"

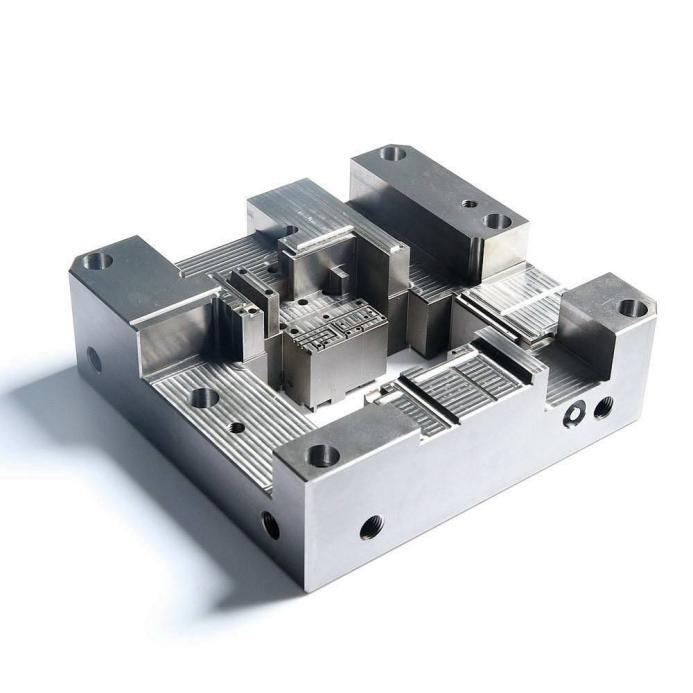

For a long time, China’s high-end CNC systems in the mold processing and customization sector have relied heavily on imports. However, this situation is changing. In recent years, domestic companies such as Huazhong CNC and Guangzhou CNC have achieved significant breakthroughs by independently developing internationally competitive CNC systems, marking a major milestone for domestic CNC systems in the mold processing field.

Core Technologies Under Control

The latest industry data show that domestic CNC systems have reached international advanced levels in key technological metrics such as five-axis linkage and nanometer-level precision control. Take the Huazhong CNC HNC-848 system as an example: it delivers machining precision of up to 0.001mm, fully meeting the needs of precision mold processing, while being more than 30% cheaper than imported counterparts.

Market Dynamics Reshaped

Previously, high-end mold processing enterprises predominantly chose German and Japanese systems. Today, domestic systems have successfully replaced imports in many cases. Most industry leaders now acknowledge that the market share of domestic CNC systems in China’s mold processing market has grown from less than 10% five years ago to 35% today. It is expected to exceed 50% within the next three years.

Collaborative Innovation Across the Value Chain

This breakthrough has driven upgrades across the entire value chain:

The lifespan of domestic CNC tools has increased by 200%.

Mold processing efficiency has improved by 25%.

Overall enterprise costs have decreased by 40%.

According to experts from the China Mold Industry Association, the rise of domestic CNC systems has not only broken technological monopolies but also enabled China's mold processing industry to achieve true autonomy and control. As smart manufacturing continues to advance, domestic systems are poised to play an even greater role in the field of precision machining.

"Industrial Upgrading in Progress: CNC Technology Propels Micro Mold Manufacturing to New Heights of Intelligence"

The rise of domestic CNC systems has not only reduced equipment procurement costs for mold enterprises but also provided strong support for the autonomous and controllable development of China’s mold industry. With continuous improvements in the technology of domestic CNC systems and under the strategic guidance of "Made in China," this technology-driven industrial transformation is deepening.

In the future, it is expected to achieve breakthroughs in more high-end mold processing fields, further enhancing the international competitiveness of China’s mold industry.

Previous:Cost Reduction Without Comprom

Previous:Cost Reduction Without Comprom Back

Back